- Home

- >

- Stamping Business

Ogihara Stamping Business

Ogihara mass-produces pressed parts for automobile bodies for domestic automobile manufacturers. There are two types!

① Production integration type

By manufacturing the molds for our main products in-house, we produce high-quality pressed products with low-cost, high-productivity molds that are suitable for our press machines.

② Production assistant type

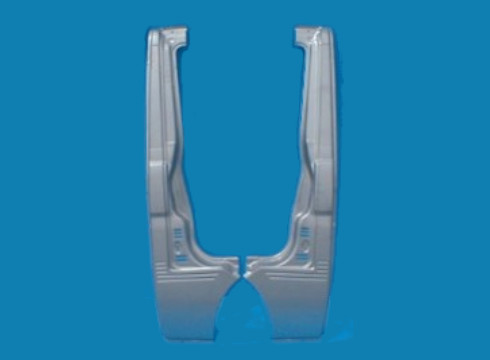

From large parts that form the roofs of large trucks to small and medium-sized parts that form the frame of the car body, we make improvements and fit the molds of various specifications of our customers to our versatile press lines for large, medium, and small sizes. If you have any trouble with parts production, please contact us.

Press Equipment

Ogihara’s large automatic 3,000-ton transfer press has been in operation since its introduction in 1981.

We handle a wide range of products, from high-tensile reinforcing parts to back door parts.

The tandem press consists of three lines: A, B, and C, and the top press of each line is a double-action type to handle products with a large amount of molding.

The A line is a line with 5 machines that can handle medium-sized products with many processes.

The B line is a four-unit production line that is good at producing small parts.

The C line is a four-unit production line that can produce large parts with a mold size of 4 m class. Ogihara Equipment.

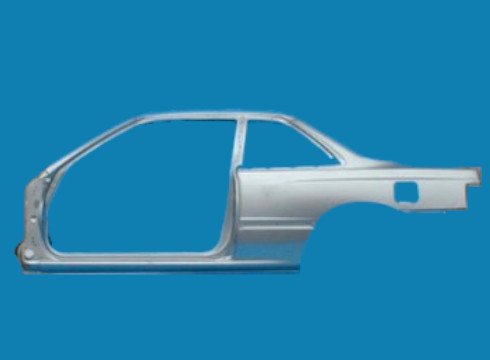

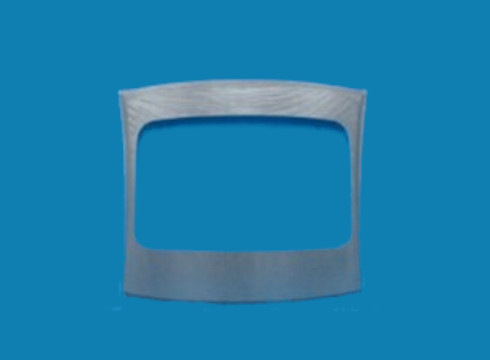

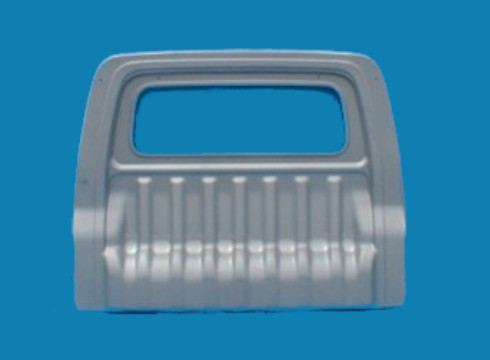

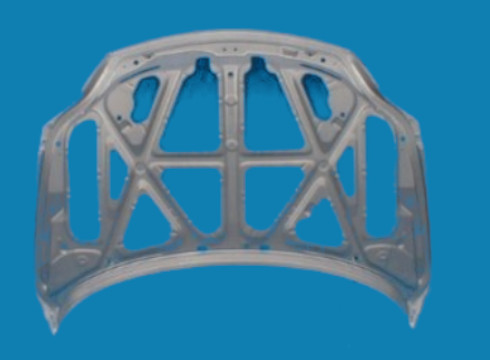

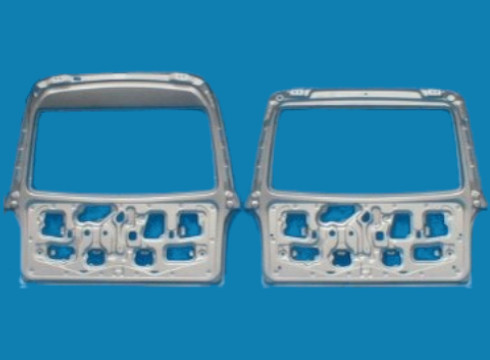

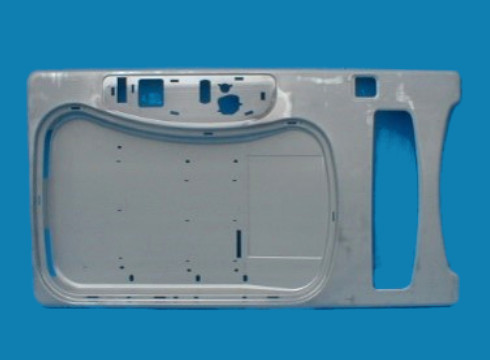

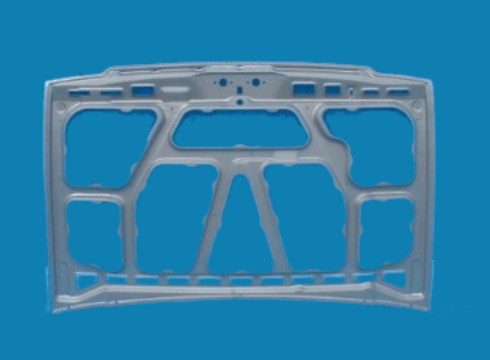

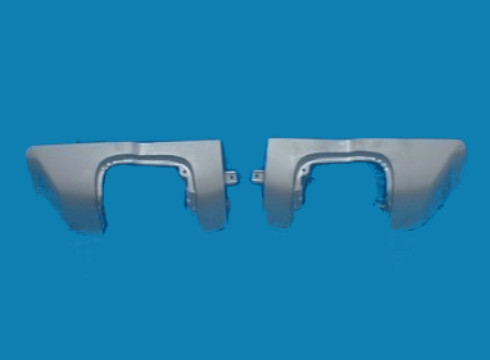

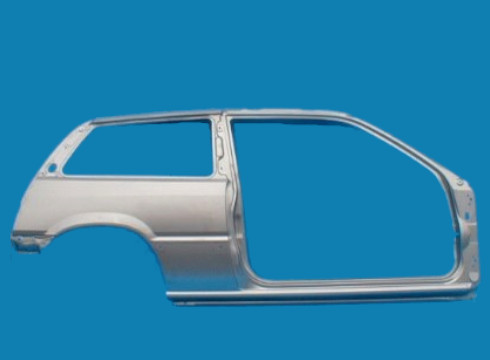

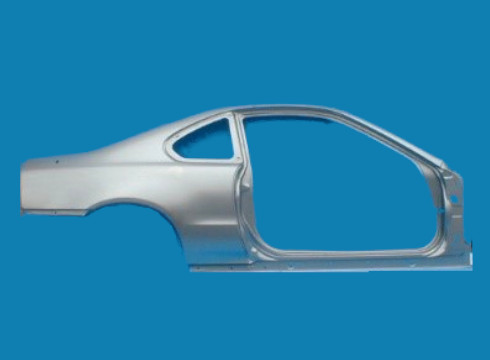

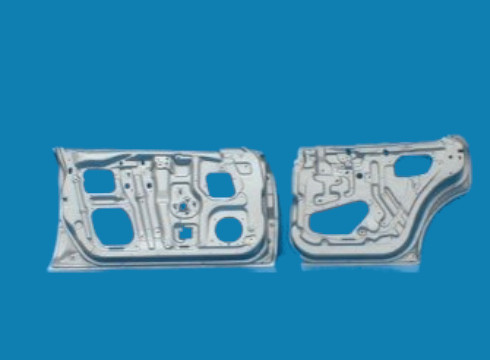

An example of production panels

From mass production to service parts, we produce a wide variety of automotive parts that meet customer needs.

We can handle all the thin sheet products that make up the body of a car, from large outer parts such as body side panels, fenders, roofs, hoods, and doors, to pillars and floor parts that form the frame of the car body.

In addition, we have also responded to the production of aluminum parts for the weight reduction of vehicles due to the shift to EVs.

These products aim to stabilize the quality of body panels through a quality control system backed by a quality management system.